Success Story – BKS: The solution for your cutting

Cutting problem in the Alu-sheet industry

When a partner encounters a cutting problem in his production process, we send immediately one of our technical sales to identify the root cause.

This is what happened to one of Kris’ customers, External Sales at BKS Belgium: « I was contacted by a customer in Flanders, who encountered dust problems and so quality cut problems. I visited the customer to have an overview of the cutting process, to find the appropriate solution. »

After brainstorming with the customer, Kris inspected the machine and noticed that this was a quite new machine in excellent mechanical condition. He had to follow another path… He thus analyzed the dust: « the mechanical scissor cut of this type of material always generates a small amount of fine dust, due to the mandatory friction of the knife with the material, but never in these quantities. »

Challenges to overcome

In an optimum production chain, every part of the chain must be functional. When analyzing nothing can be left to coincidence.

After this, we took note of some issues:

Solutions implemented by BKS

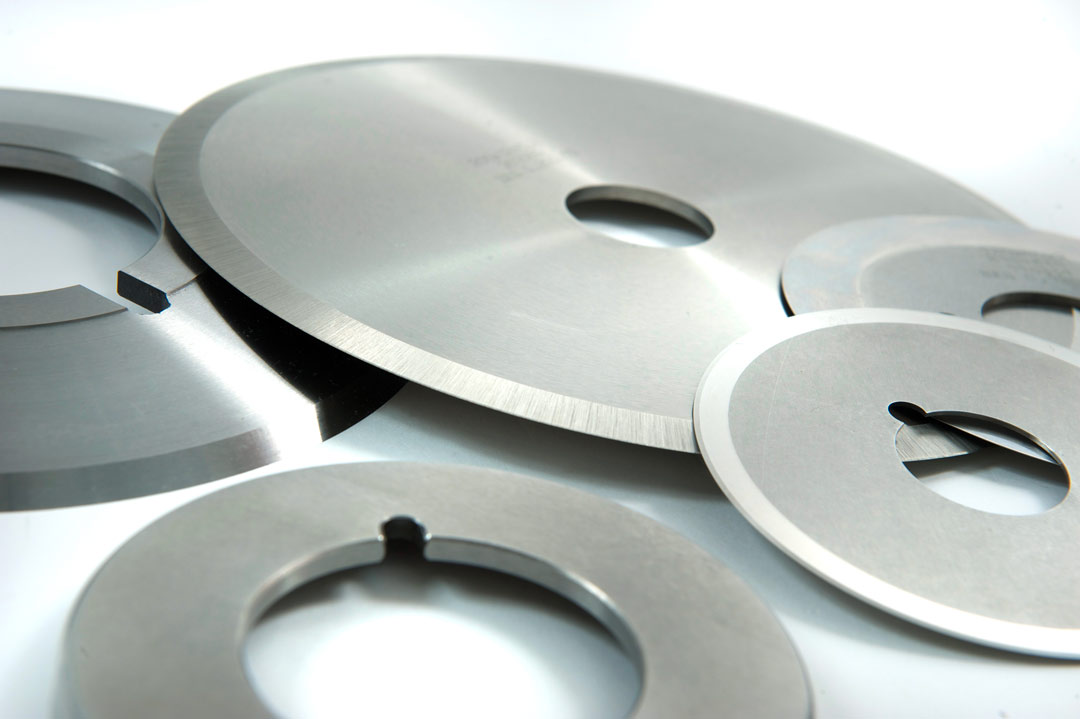

We did not only modify the speed of the knives, but also changed the type of knife holders, top and bottom knives.

A 3 hours training was given to the technical department, so they can all work in the same correct way, following the procedures.

Results

Quality cutting problems and the augmented production of dust are solved. This solution gave our customer also extra savings on production costs (much longer running time), and needs much less knives.

Do you want to be contacted by one of our technical sales to discuss your needs of industrial knives?

Contact us using this form!